Factory Brno – CZ 05

The Brno factory has a processing capacity of 500,000 liters of raw material per day. Drying of skimmed milk and sweet whey is the main aktivity of the factory

Since 1999, when it become the property of Eligo a.s., the factory has undergone several modernizations of the production equipment and reconstructions of its stock area. The increase of overall production quality and the improvement of hygienic conditions have resulted in approval of this factory to export its products into EU countries already since 2000. In 2004 we invested in new fully automatic packing equipment, which together with automatic palletization enables us to pack the products in accordance with the strictest hygienic requirements.

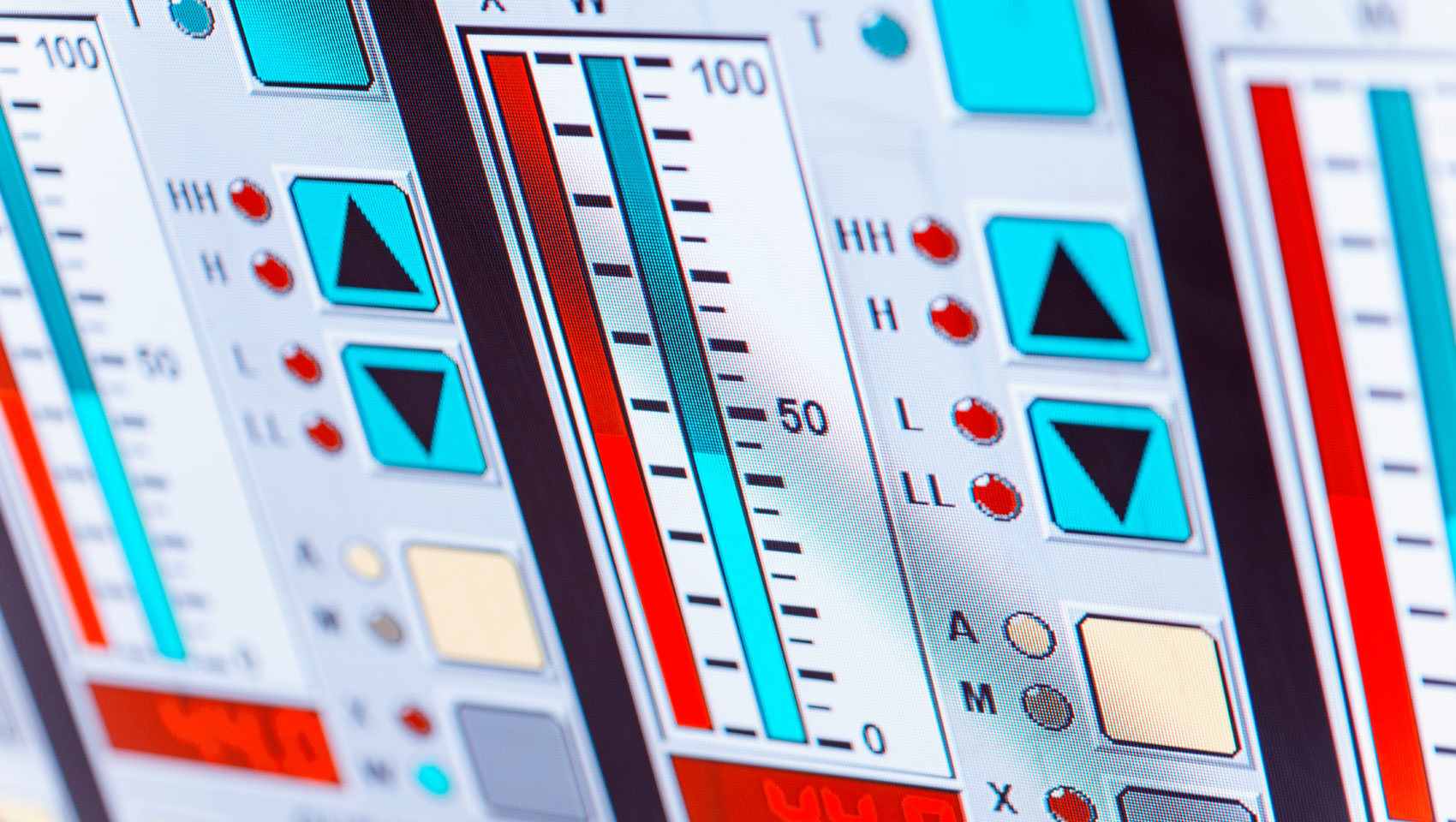

Management of process parameters and permanent control of operation are the basic preconditions of high-quality production of goods. That is why in 2003 the visual system of archiving technological data was introduced. It allows the staff to monitor the processing in real time from any workplace of the factory.

In 2006 the production equipment was reconstrcted and extanded with milk sugar crystalization technology.

In 2008 - 2009 the factory was restructured.

In 2013 the drying tower was reconstructed in order to increase its output and to save energy.

Big volume sack packaging - Big Bag - and auto-silo filling have been in operation since 2014.

The Brno factory is one of the three main pillars of Eligo a.s. which goes a long way towards satisfying our customers.

Technical data

| Processing capacity | 12.000 mt/year |

| Power of evaporative station | 20.000 litres H2O/hour |

| Power of drying tower | 2.000 litres H2O/hour |

| Capacity of packing link | 6.000 kg/hour |

| Stock capacity | about 1.700 t |

A stable team of 25 employees works in the factory. Regular professional trainings, functional system of quality management, safe food production and low fluctuation have always been highly rated by our customers.